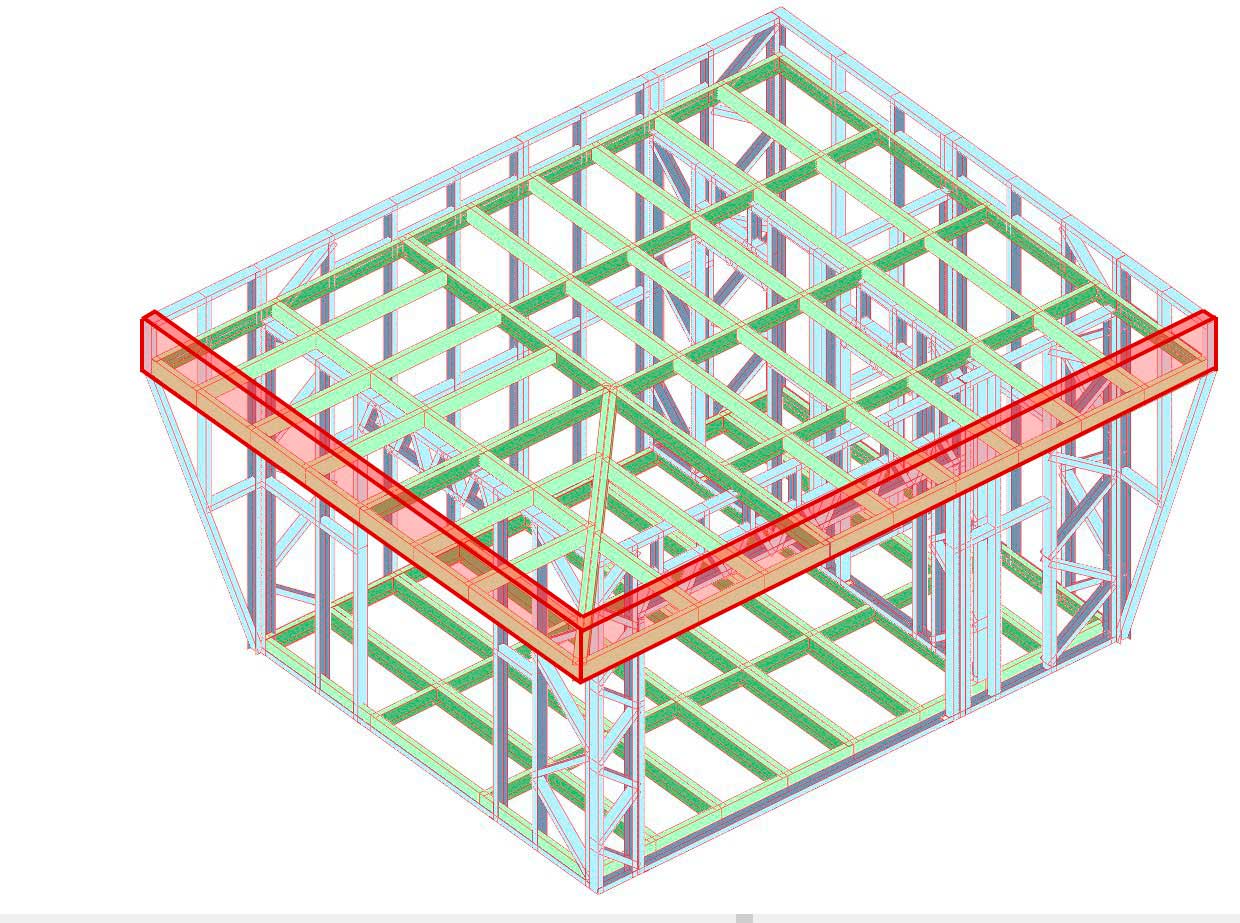

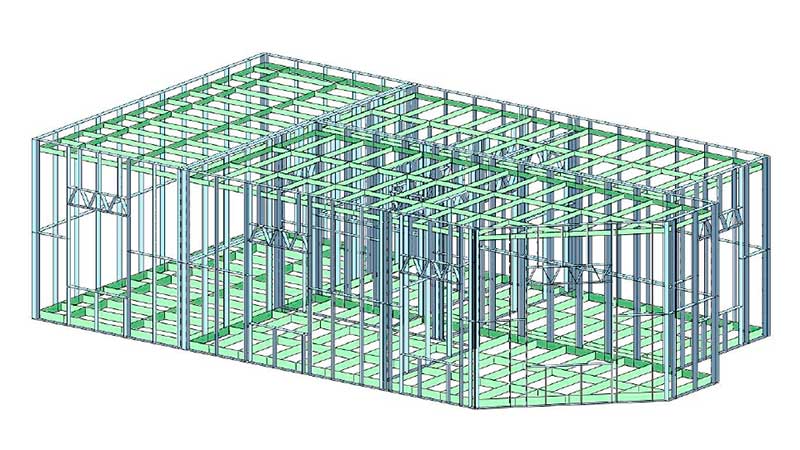

The planning stage in the steel framing construction process is key to creating a well-defined project. For this, it is essential to take care of even the smallest detail and leave nothing to chance. This will allow us to control costs, improve construction speed and ensure millimeter results through technological systems.

Planning in the Steel Frame construction system

Planning is essential in construction for several reasons, including some such as:

It allows the project to be completed within the established term and within the budget. Efficient planning makes it easy for each project to be delivered on time and all planned deadlines are met.

Helps minimize potential risks and identify problems before they occur. Thanks to planning we can prevent many risks that can be carried out in the construction process, in addition, it reduces delay times and additional costs. On the other hand, it allows identifying and mitigating risks that may endanger the safety of workers, as well as the final quality of each project.It facilitates efficient communication between the different parties involved in the project. Through detailed planning, architect, owner, contractors and subcontractors, they will be able to be aware of the proposed objectives and the evolution of the project.

It allows to maximize efficiency. Good planning leads to proper coordination and scheduling of construction tasks, facilitating the efficient use of resources, including time, personnel, and materials. In this way, construction time is reduced.

Improves the quality of the building. Planning enables problems to be identified and resolved at an early stage, helping to ensure the quality of construction and final project.

In general, planning is essential to achieve a correct optimization of resources, both in the use of space and in the materials used, since it allows to identify on time and minimize unnecessary costs.

Good planning ensures the accuracy of each of the profiles with which the steel framing construction process works. It is one of the most important characteristics, since these types of constructions are exact, it does not allow errors. This is achieved by working with steel profiles with standardized dimensions and exact cuts.Sometimes this part of the process is the most expensive in terms of time spent, however it is then recovered during the construction process on site. In this way, in addition to saving time, waste is reduced.