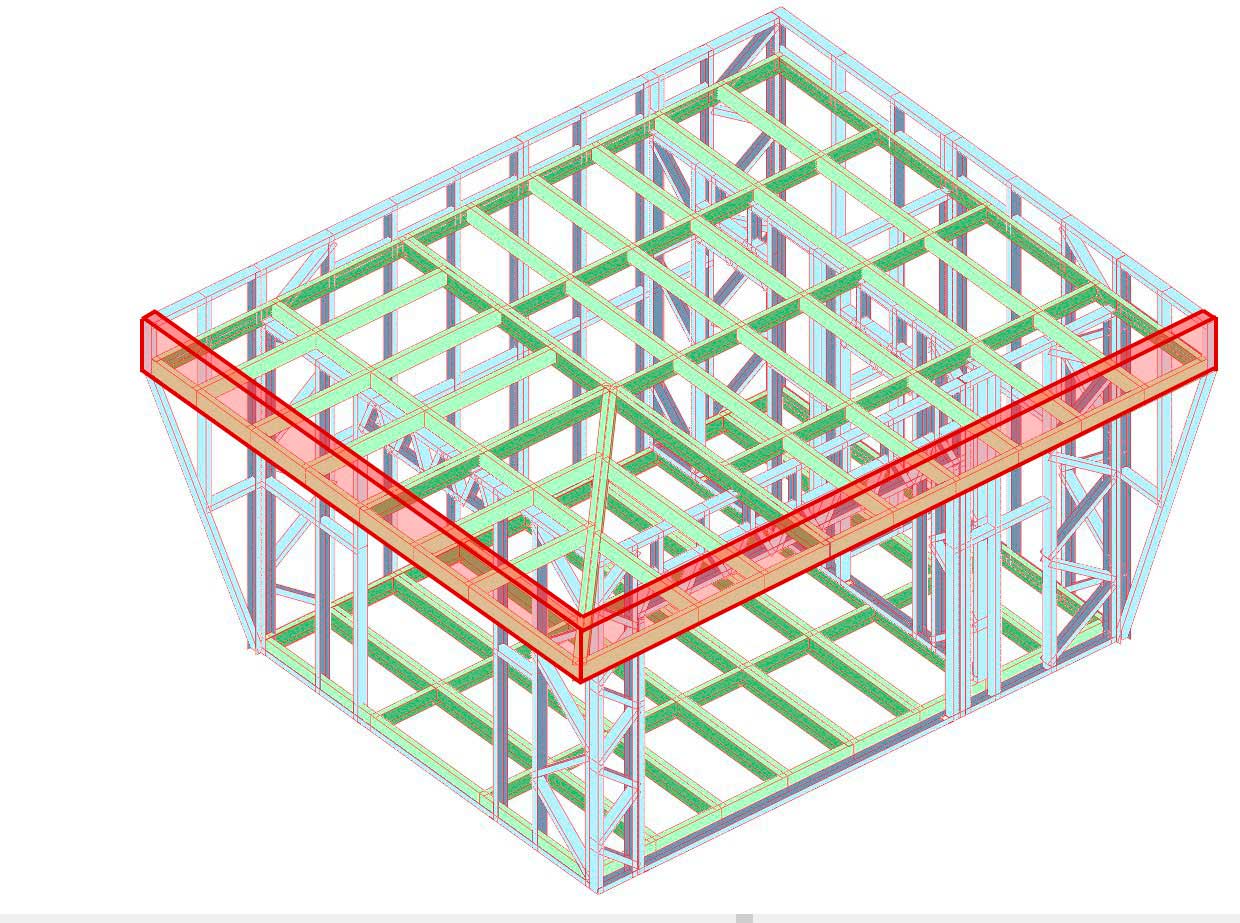

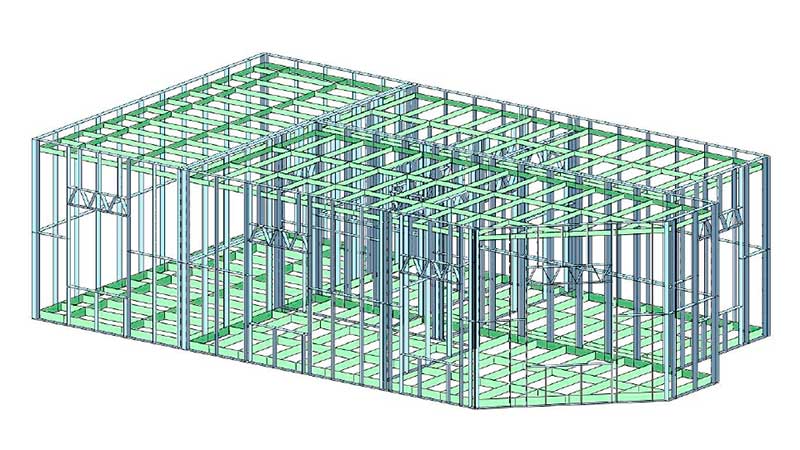

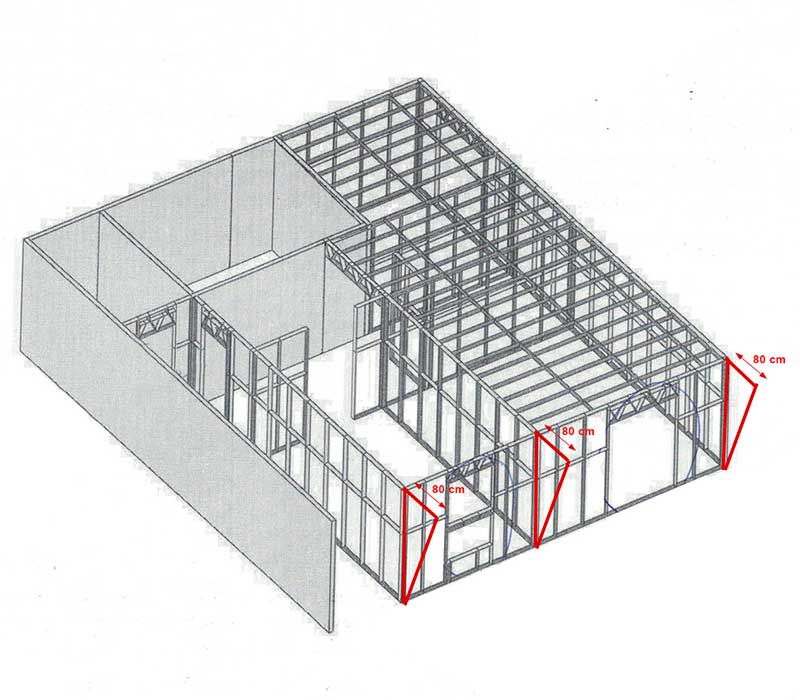

Example of assembly execution of our light cold-formed steel structure, steelframing.

There are issues in life that are not forgotten. When the inconveniences are of the magnitude of a pandemic such as Covid19, the will to keep pushing and the desire to do things better and better are determining factors for success.

Thanks to having an industrialized, agile, fast and safe system, we were able to comply, despite the necessary restrictions due to the Covid19 situation, with the assembly rhythms of the structure of this house.

On the 13th we began the assembly of the house and as can be seen in the video, it took 8 working days to completely finish the structure.

«Building has never been easier»